Today was the day where I got my hands on to the Ninja Flex that we bought a few weeks ago.

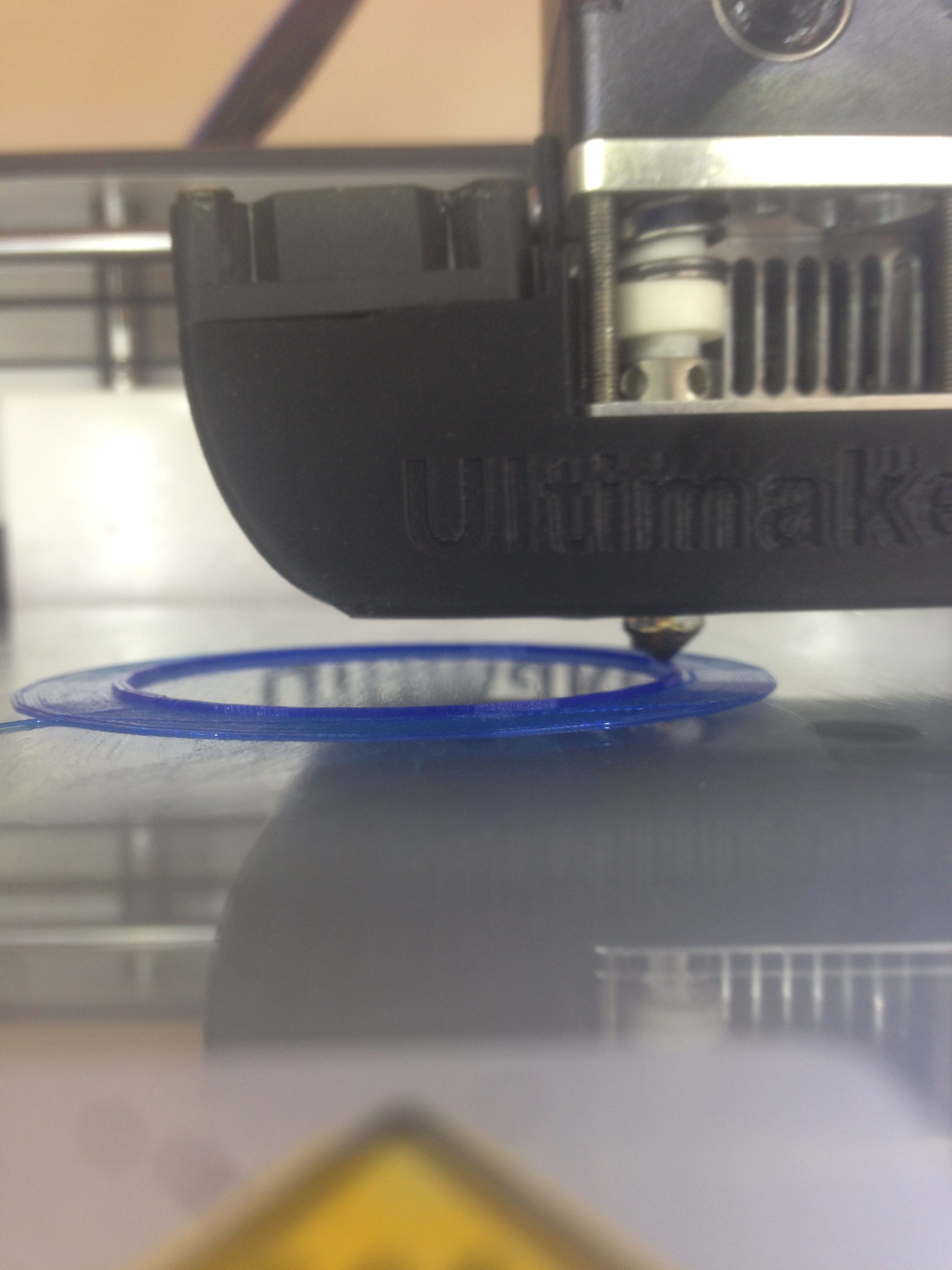

As soon as I got it I put it on the Ultimaker and printed the test file Matthew had made for me a little while ago.

The only print settings I had to change were:

Extruder Temperature: 225°C – 235°

Platform Temperature: 40°C

Disable the retraction.

With the 4 prints I’ve done with this so far, I haven’t had any issues. The real test will be when we do the real belts.

Jack had an idea to run a force test to determine just how strong they were. He talked to Mr Stock, who had the perfect tool for the job: a Wireless Force Acceleration Sensor. The results are quite extensive, so expect a blog post later with more information.