Today I used one of the prototype chassis to measure the length of each belt. I attached the servos and wheels, and then used string to find the exact length the belts needed to be.

I cut the string and measured the length (or circumference, as the belts would be designed as a circle) and extrapolated the value to find the radius (seeing as though sketchup circles take radius measurements).

Measurements:

Circumference: 57.25cm

Therefore as r=c/2π, radius = 9.11cm

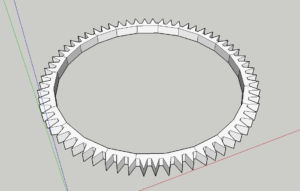

I played around with different designs for the belt, with different sized external teeth. I eventually settled on a spiked teeth version:

I tried other variations, including rounded teeth as well as small vs large rounded and sharp teeth. Upon consultation with everyone else, they unanimously selected the sharp 1cm long teeth.

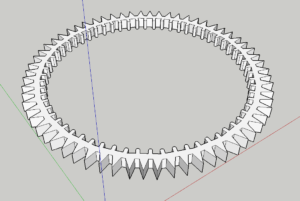

I then created smaller teeth on the inner ring to stop small rocks and dirt from getting in between the belt and the wheel, pushing the belt up. Here’s a hastily drawn diagram of what that means:

This is what is supposed to NOT happen.

In order to hopefully reduce the severity of this is why I put teeth on the inside of the belt.

Again I asked my teammates’ opinion and they agreed that the inner teeth should be small and rounded.

Having finalised this design, Aaron started printing them in Ninjaflex. They only just fit on the Ultimaker buildplate, which is lucky as if the robot was any bigger then it wouldn’t fit at all and we wouldn’t be able to print these belts in a circle, and I’d have to do some fancy curves in the design which would take a lot longer to prepare for printing.

Progress!