The wheels we made for the Mark III robot did pretty well. The new polyurethane tires were excellent, they had plenty of grip, were basically indestructible and they maintained their grip over many hours of use. The hubs worked pretty well… well, most of the time.

Apart from the structural issues due to low infill when printing, there was one issue. It was very tricky to get the tires on to the hub, and even harder to get them off. In fact, I had to break the hub to get the tire off, the one and only time we ever attempted to remove it.

So I set about designing a new wheel hub system. This time one where the tire could easily be removed.

The S.A.R.T. Split-System Hub™

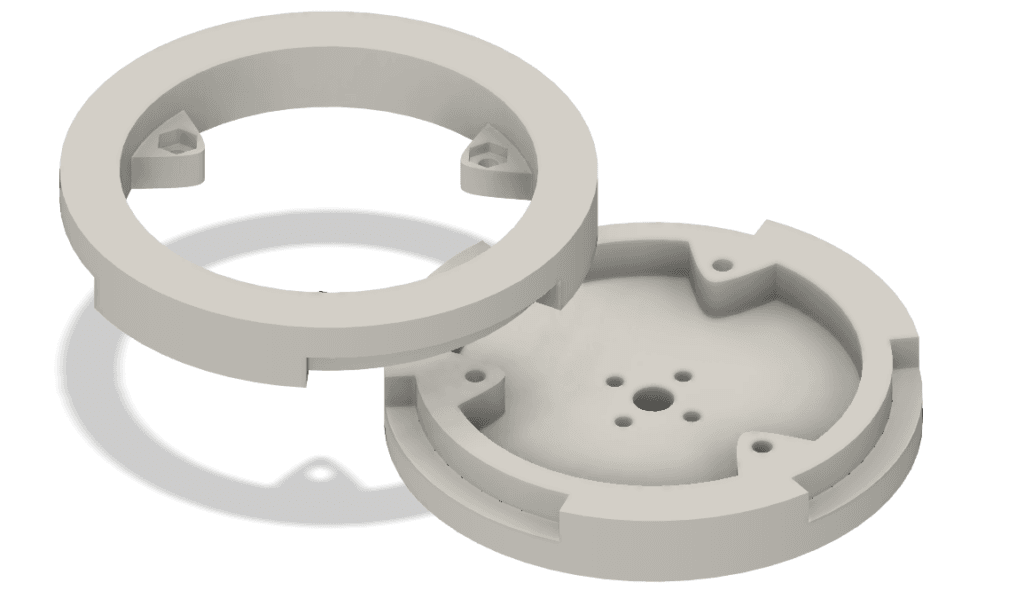

I came up with this:

This new two-part hub system clamps around the tire, which is secured with three M3 bolts

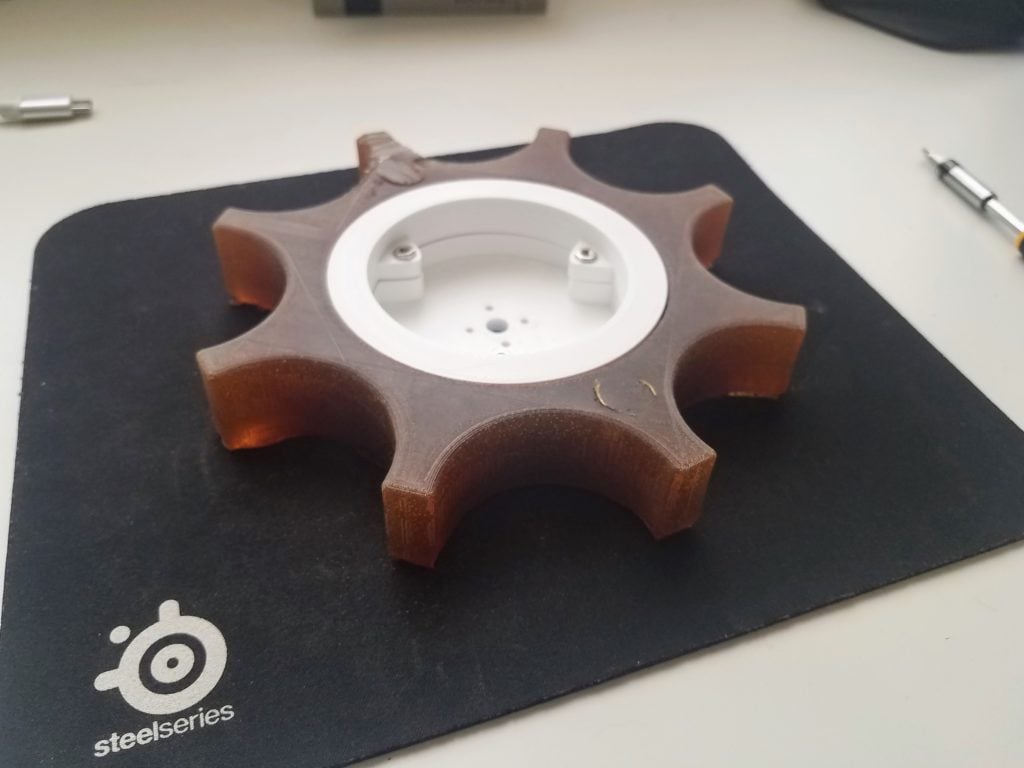

Here’s how it’s installed:

Pretty easy right? It’s super easy to install, it’s secure, and it looks pretty cool!

I printed it with a pretty decent infill, but surely it’s still lighter than our original design… right?

Weighing Up The Pros and Cons

Our original wheel design (the one with teeth) used significantly smaller hubs. This changed when we made the PVC pipe ones, which feature a larger hub, meaning less polyurethane was used.

Now, our original justification for the smaller wheel hubs was weight, since presumably the polyurethane would weight more than the 3D printed hubs. It also saves on costs. Filament is cheaper than the polyurethane.

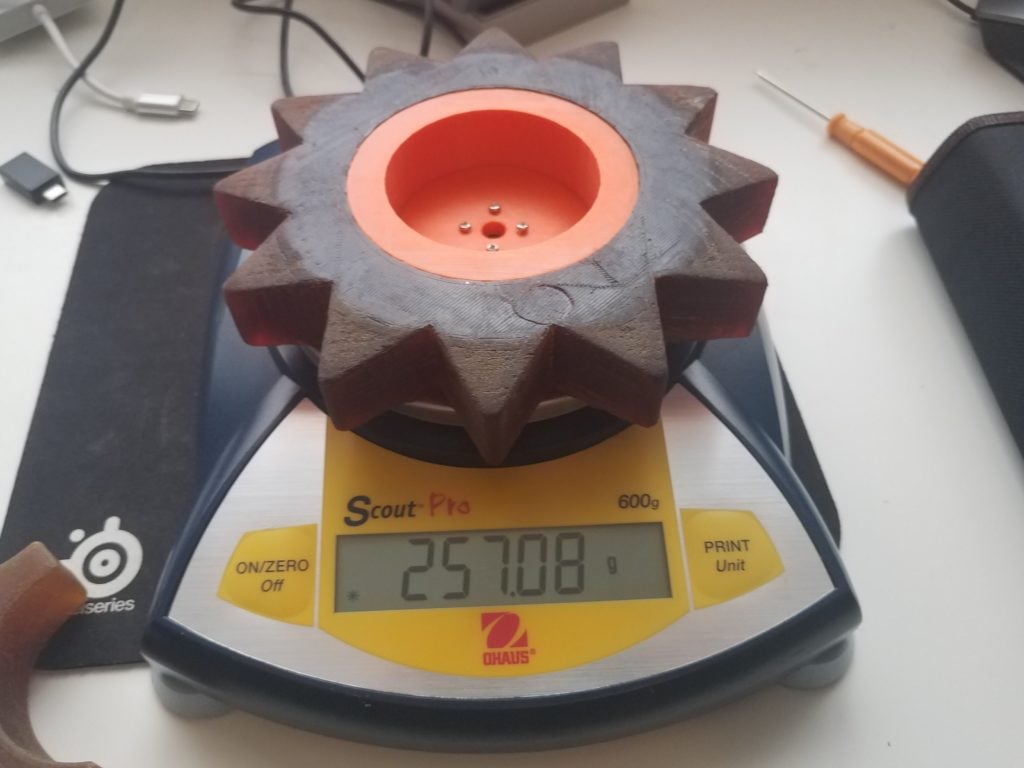

As you may notice, the original wheel came in at 257g. The PVC style one with the larger hubs (and also, worth noting, had a poor infill like the original wheel) came in at 223g. So we did manage to save a good ~35g with the newer wheel and hub design.

However, the new split system wheel is 264g. Let’s remove 4g for the nuts and bolts, to make that 260g. That’s 37g heavier than the old hub of the same shape with the same tire.

Not ideal.

So how can we improve on this? How can we make it lighter?

A few things came to mind…

Ways To Weigh Way Less

When slicing in Cura, it estimated that it would use 86g of filament to print the two parts of the hub. The hub ended up actually weighing 79g in total, excluding nuts and bolts.

Option A – Lower infill

I used 80% infill on both parts of the hub. That’s a lot. You could easily take that down a bit. Especially since we’re already using a strong infill pattern (cubic).

Cura says, using 60% infill instead, this would take it down to a total of 74g, excluding nuts and bolts. In reality, probably looking at 69g when weighed.

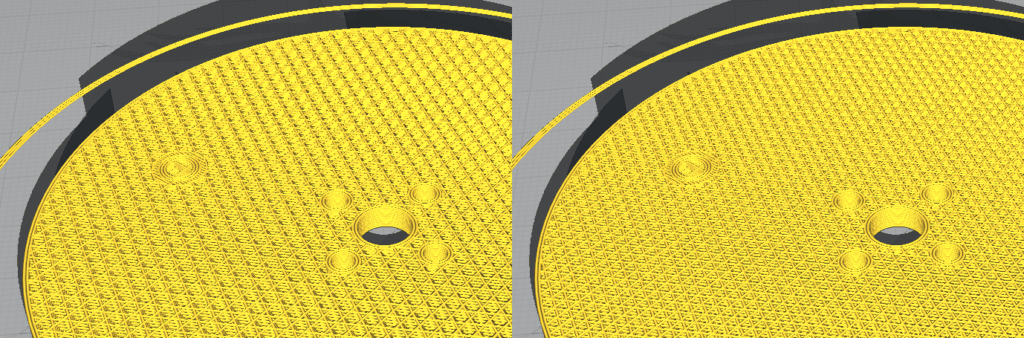

Option B – Different infill pattern

We could use the cubic subdivision infill pattern, which while still strong, uses much less material. If we used that for both parts it would use a total of 75g of filament according to Cura (in reality that would be even less when weighted, perhaps around 70g without the nuts and bolts).

Can’t tell any practical difference? Nah, me either.

Option C – Lighter front half

The front half doesn’t take much of the actual force. The main strain is going to be against where the hub connects to the motors, as seen in our drop test video.

This would bring the front half down from 33g at 80% infill to 24g at 40% infill. With the original back half, that’s 76g in total.

It’s a small saving over the 60% for both one, so this one is pretty optional, depending on what you value more.

Option D – All of the above

Individually, here’s a summary of the results from the previous options:

| Individual Change | Before | After |

|---|---|---|

| Infill to 60% | 86g | 74g |

| Infill pattern to cubic subdivision | 86g | 75g |

| Front half infill to 40% | 86g | 76g |

Let’s have a look what happens when we put it all together. This is each of the previous changes, but put together:

| Sequential Change | Before | After |

|---|---|---|

| Infill to 60% | 86g | 74g |

| Infill pattern to cubic subdivision | 74g | 67g |

| Front half infill to 40% | 67g | 64g |

We can take it from 86g to 64g in Cura. In reality the actual weight would be around 60g, a solid improvement from our original actual weight of 79g.

Across the four wheels, this gives us a total saving of 76g on the robot. I have no idea how much of a different that will make, but if there’s one thing I learnt from writing resumes and sponsorship prospectuses, throw around a lot of numbers and people will throw around a lot of money.

Final Thoughts

There you go. Some new hubs and some ways they could be even better. Now all that’s left is to design some new tires to go on them! Stay tuned for another ‘wheely’ good day!