The 29th of July was an opportunity for the S.A.R.T and the four other qualifying teams – Blue Storm, Tupac, Kings Legacy and Magistry – to run practice trials through the final maze configuration before finals.

Above: The RMRL team assemble the final maze. Taken on the 29/07/2017 at 12:53 PM.

While construction was underway, we continued working on our sensor multiplier code.

Above: Spread across two tables, we continue working on our sensor multiplier software. Taken on the 29/07/2017 at 12:54 PM.

After some hours, we had QR code reading working, a somewhat accurate hazmat sign detector, and rudimentary motion detection all but implemented. At this late stage, we decided our time would be best spent working on the two-way audio communication that could get us 2 multiplier points.

We discussed the idea of using some existing software using VoIP. However, we needed something that did not need to connect to servers for authentication. Due to our internet situation at the venue, we found it difficult to do much with this idea. Compounded with the fact that we didn’t know what the impact audio streaming would have on our existing data streams, we found the prospect of wasting hours on trialling various LAN VoIP clients and servers a daunting task.

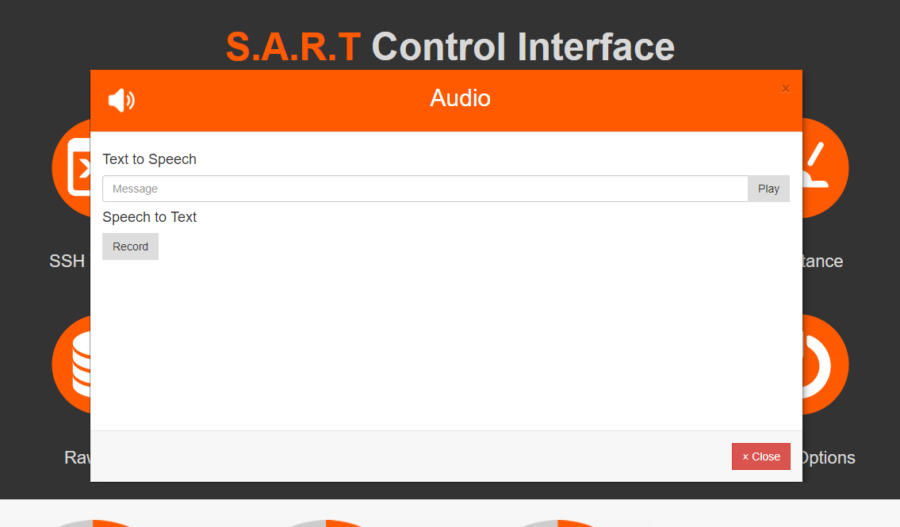

Instead, I added a new “audio” panel to the S.A.R.T Interface while Ryan and Pham worked on two small Python programs – text to speech, and speech to text.

Despite the inelegant solution, we were confident it would work for the purposes of the test without any other recourse.

Above: The new audio panel allows the controller to send a text to speech message, and receive one back through speech to text.

Eventually, the new maze was completed and we could start doing practice runs. We spent a few hours switching between practice runs and charging LiPos and working on updates for the audio features. We could have continued all day if it wasn’t for Graham’s discovery.

After one particular run, he picked up the robot and noticed a sagging servo. Giving it a wiggle, he handed it off to Matthew, explaining the problem. The entire corner of the chassis had cracked along a weak point of the print, where the layers had not adhered properly. With no way to fix it at the venue, and the final competition looming, we left immediately to fix the robot at the hotel.

Whilst on the train, we compiled a list of things we needed to get from BIC CAMERA. Double sided tape to fix the PoE injector mounting inside the control panel. Canned air to clean out the robot, which was becoming clogged with sand. A USB Mini B for testing the Arduino, which Ubuntu wouldn’t connect to. A HDMI to VGA adapter for connecting the NUC to a display, as we had lost ours and had to borrow one from Kings Legacy. Acetone to weld the ABS back together on the robot.

In true BIC CAMERA style, we were able to find everything, except the acetone. Instead, we opted for some epoxy. Gerry chose a pack containing two tubes of thick clear liquid – obviously 100% epoxy, no time to translate it. Let’s buy it and get out of here before the store closes!

Back at the hotel, Matthew dismantled the robot completely for cleaning with the canned air. Riley washed the wheels and applied new plasti-dip for maximum grip. When the chassis was empty (except for the servos), Gerry applied the epoxy to the crack. For good measure, we painted over all the servos with the excess epoxy and waited for it to dry.

It didn’t.

“It’s not epoxy,” Gerry said finally. He postulated that we had in fact bought rubber epoxy, which wouldn’t form the strong bond we desired. With BIC CAMERA closed for the day, he and Graham ran to the “7-Eleven” and “Mini Stop” corner shops in search of real epoxy, however, there was none to be found.

After they returned and after we sat staring at the robot for another 20 minutes (giving the epoxy further time to dry), we decided the bond was actually rather strong. We had another problem though – the servos weren’t going to come off ever again. If we damaged one during the competition, we would never be able to replace them.

To boost morale, Matthew shared some doughnuts from Mini Stop and Gerry shared a story about how dead the doughnut made him feel.

At this stage, it was midnight. Gerry sent Riley and Aaron to bed, for they were to be “moral support” on the final day of competition, considering everyone else would be tired from what was to come. We were soon ushered out of the common area by the hotel staff, who were about to close the lobby.

Gerry invited everyone up to his room to continue working – as Pham explained, he had a non-smoking room with double bed and plenty of extra space, including a desk!

Matthew reassembled the robot while Ryan, Pham and I continued working on the audio software. After over an hour of coding on the control panel and fixing some bugs (that arise from Pham coding everything completely without even testing it. I should mention that what he does is amazing – it’s like he compiles and runs everything in his head, so he can write a couple hundred lines of code and then when we run it just have to fix a couple of variable names or whatever and it just works…), we had a complete audio system with 90% accurate translation.

Above: Gerry provides his input while we work on the audio text to speech/speech to text features. Taken on the 30/07/2017 at 1:55 AM.

Somewhat satisfied, we went to bed at 2:30 AM.